Things about Premier Aluminum Llc

Table of ContentsPremier Aluminum Llc Things To Know Before You BuyEverything about Premier Aluminum LlcPremier Aluminum Llc Things To Know Before You BuyWhat Does Premier Aluminum Llc Do?

(https://www.awwwards.com/premieraluminum/)Commonly, a purchaser's primary responsibility was to find professional and receptive suppliers. Sometimes, purchasers assumed that any kind of distributor eager to contractually fulfill the purchase need was qualified. Nonetheless, making use of affordable and unqualified distributors can trigger quality concerns, and lost time and cash in the long run. To assist you through the process, below are some things to take into consideration when selecting the appropriate steel spreading distributor.

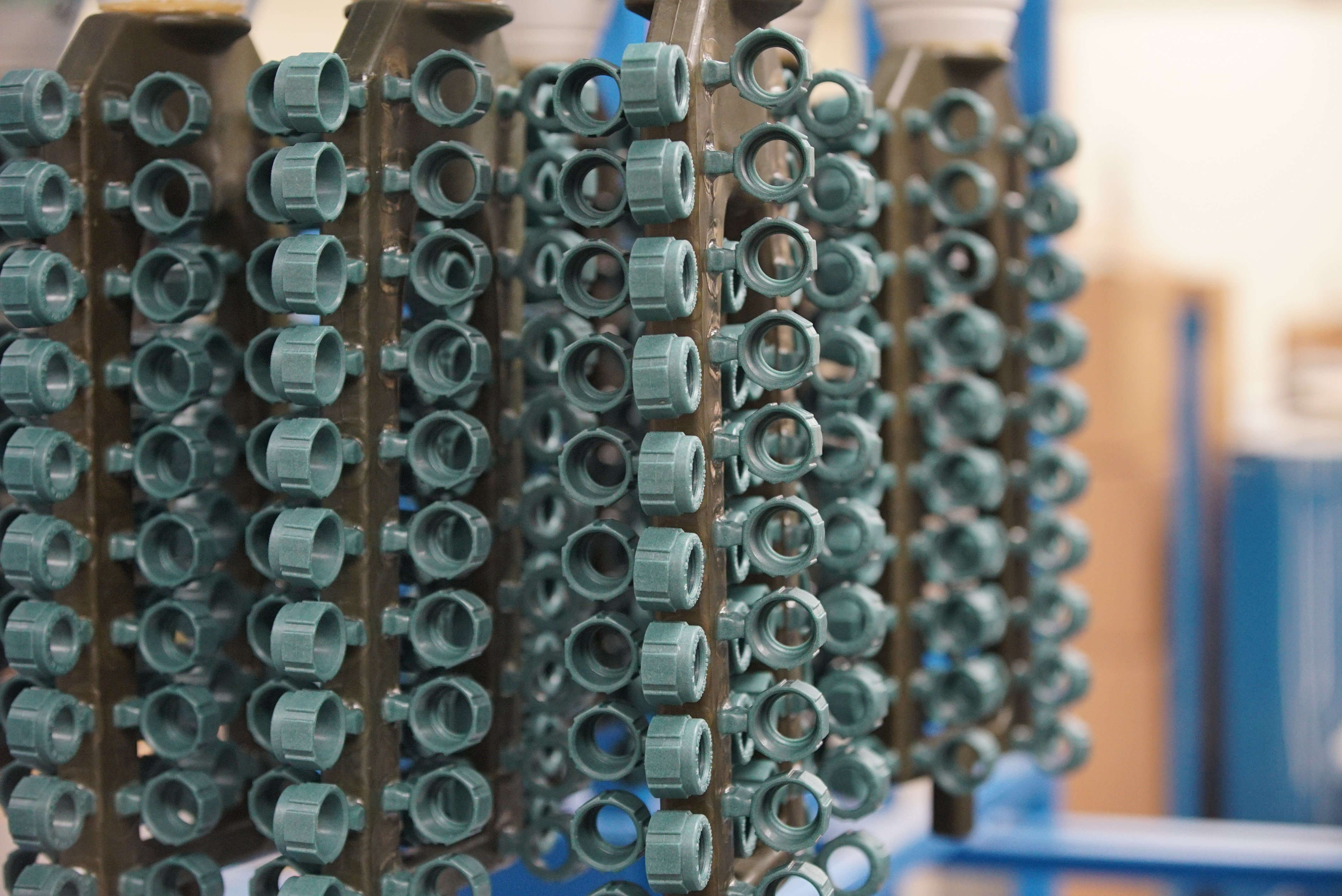

For instance, a business that only uses the financial investment spreading procedure will try to market you on why that process is best for your application. However what happens if utilizing the sand spreading procedure is best for you and your demands? Rather, search for a distributor that uses an array of casting processes so the very best choice for YOU is selected

If working with a solitary source for all of your spreading requires is very important to you, the vendor requires to be diverse in its capabilities. When integrated with various other integrated capacities, this can assist simplify and press the supply base. When picking the right spreading provider, mindful consideration needs to be offered to high quality, solution, and rate.

What Does Premier Aluminum Llc Do?

Purchasers progressively pick casting providers that have machining capacities. This can prevent dispute if defects are found throughout machining. If a 3rd party is machining, it may result in "finger-pointing" concerning who is at fault. Is it a spreading issue or a machining issue? If the casting vendor uncovers an issue throughout machining, the issue is solved quicker without any conflict over whose fault it is.

What do you need from your casting distributor? Are you looking for somebody to simply supply a steel element to your front door or do you require much more?

Some foundries are minimal or specialized. Make sure the provider can meet all your material or alloy needs to get rid of the requirement for several suppliers.

Premier Aluminum Llc Fundamentals Explained

Study the vendor's web site. Talk to a sales representative or company affiliate.

Aluminum is additionally lightweight and has excellent corrosion resistance, making it optimal for applications where weight and resilience are necessary aspects. Furthermore, light weight aluminum spreading is an affordable technique of production, as it needs less power and resources than other methods. Iron casting, on the other hand, includes pouring liquified iron right into a mold to develop a preferred shape.

Premier Aluminum Llc Can Be Fun For Anyone

Iron casting is also able to stand up to heats, making it appropriate for use in applications such as engine components and commercial machinery. Nevertheless, iron casting can be a lot more expensive than aluminum casting due to the greater expense of raw products and the energy needed to thaw the iron. more helpful hints When making a decision in between light weight aluminum casting and iron casting, it is necessary to take into consideration the particular requirements of the application.

In conclusion, both aluminum casting and iron casting have their own one-of-a-kind benefits and disadvantages. There are three sub-processes that drop under the group of die casting: gravity pass away casting (or permanent mold casting), low-pressure die spreading and high-pressure die casting. To obtain to the finished item, there are 3 main alloys utilized as die spreading material to choose from: zinc, light weight aluminum and magnesium.